Description

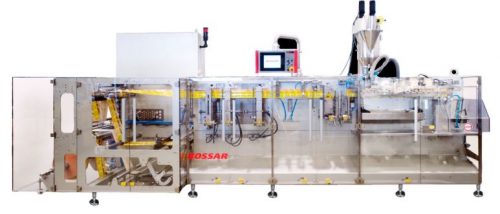

The B 3700 HFFS machine is specially designed to fill shredded cheese and powder dairy products, fulfilling the sanitary standards for the dairy industry: WDA, USDA and UL. And it can pack also non-dairy products that require a packaging machine with sanitary design.

For sanitary requirements, it is fully constructed in stainless steel and titanium, and zipper insertion is an option.

This flexible packaging machine can manufacture flat and stand-up pouches in duplex, fill up to 2.000 cc of product, and reach a speed of 140 pouches per minute.

TECHNOLOGY

-

Mechanical

Mechanical technology consisting of cams.

TRANSPORT

-

Walking beam

Traditional walking beam transport system consisting of beams and grippers. They hold the pouches and transport them through the different stations, from the pouch forming to the pouch closing.

APPLICATION

-

Clean & ultraclean

Clean and Ultraclean levels achieved are achieved during packaging by means of laminar flow, U.V. lamps and/or hydrogen peroxide. These applications are required to fill fruit juice, compote, yogurt and dairy products.

-

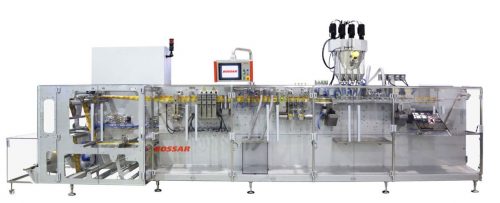

Mirror machine

Placing one standard machine in front of the other operating the opposite direction makes operating easier and reduces staff required to control them.

| TECHNICAL FEATURES | ||||||

| Execution | Format range (mm) WxH | Volume max.(c.c.) | Speed up to(Pouches per minute) | |||

| Minimum | Gusset | Maximum | Gusset | |||

| FLT-2 | 140 x 140 | – | 185 x 380 | – | 1500 | 140 |

| STU-2 | 140 x 140 | 44 | 185 x 380 | 50 | 2000 | 110

|

REQUEST FOR CALLBACK