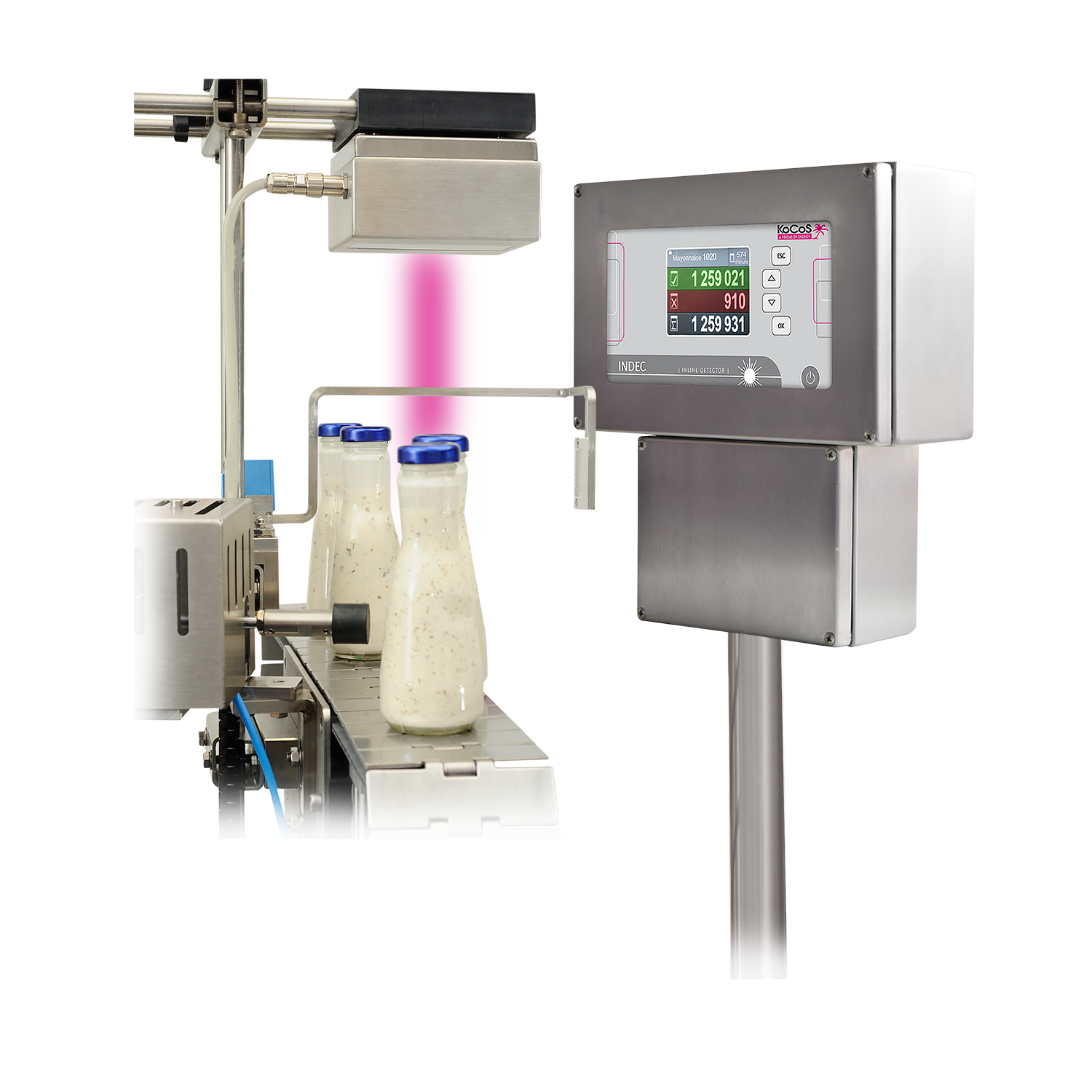

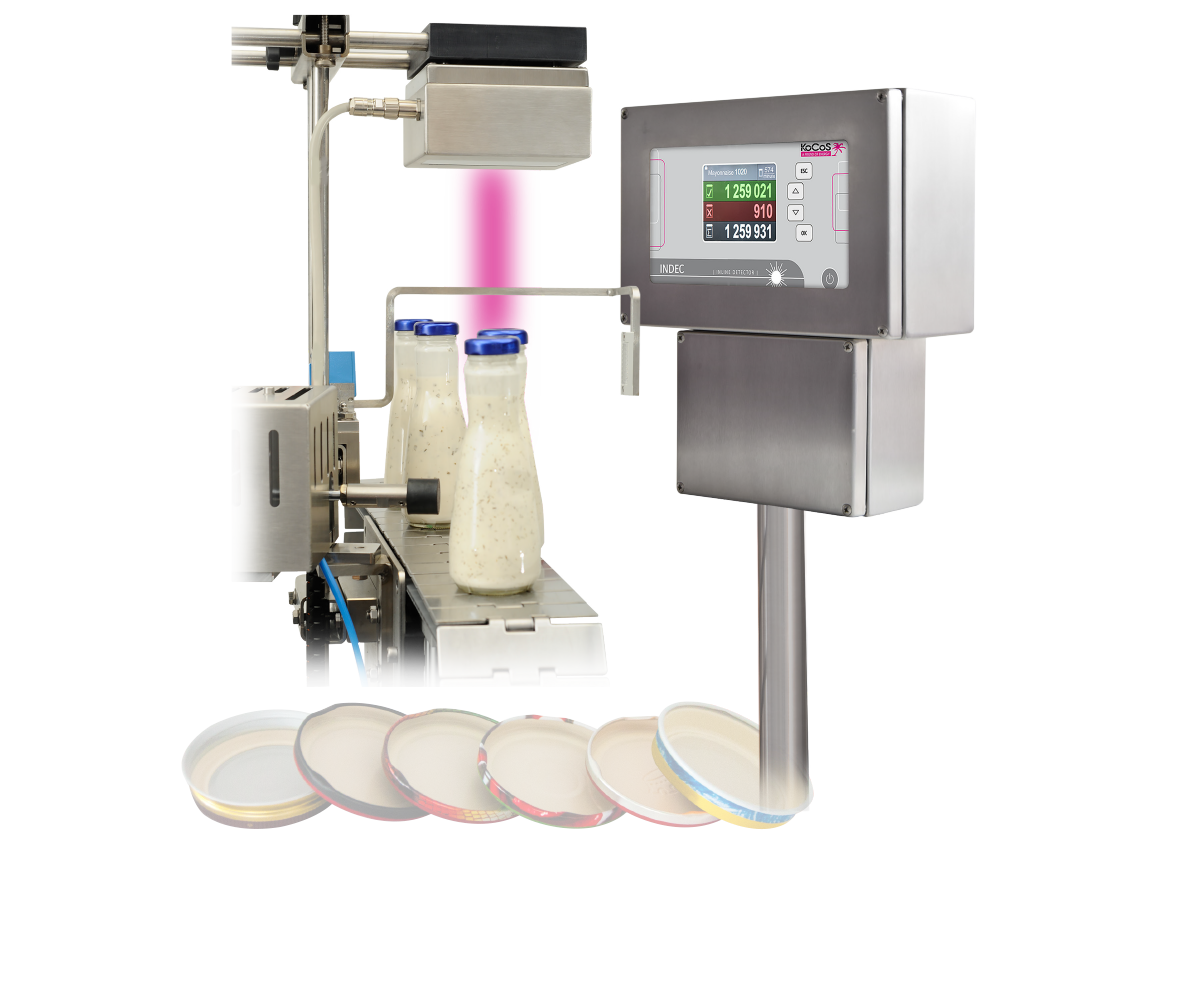

INDEC VACUUM INSPECTION SYSTEM

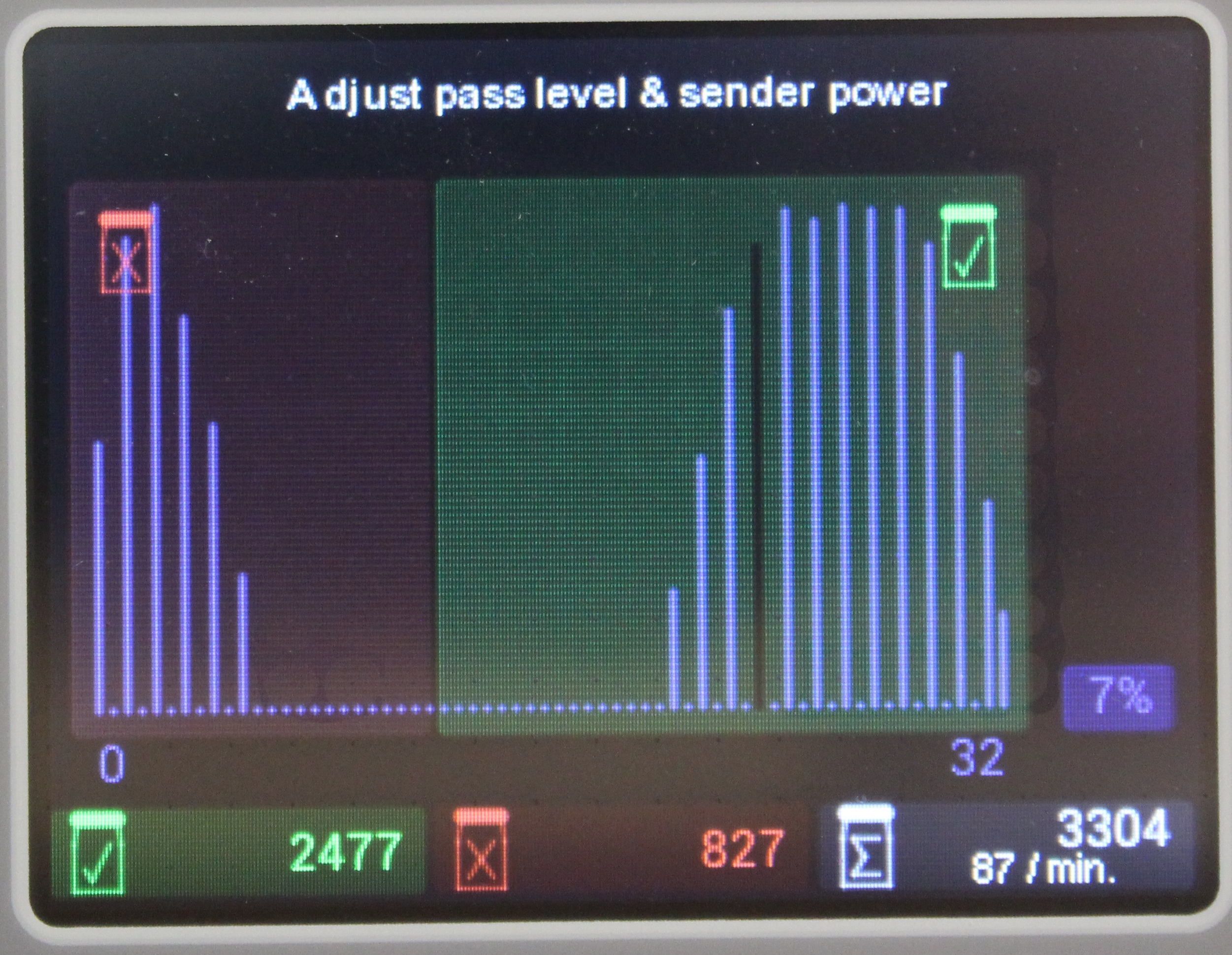

The INDEC test device monitors containers, such as bottles, jars and cans, testing them for leak tightness fully automatically within the production process by means of a non-contact inspection. Containers which show insufficient vacuum, cocked/tilted caps or missing caps are reliably identified and separated from the rest.

The following film shows the operation, working method and functionality of the very sensitive INDEC vacuum test system at a customer of KoCoS.

Ensuring that products meet the highest quality standards is absolutely essential in the manufacture of food.

Leak-tight product containers have a major role to play here. Leakages allow the contents of a container to get out, but more importantly they also allow germs to get in, rendering the contents unusable.

INDEC vacuum test systems monitor containers for leak tightness fully automatically within the production process. Equipped with an optical sensor, INDEC can be used for closures made of any material, including composite or plastic lids and twist-off lug closures made of metal. All common closures can be measured with one and the same sensor head.

CHECKWEIGHER

A checkweigher ensures the control weight of the 100% of your production, rejecting under-weight products and minimizing overfill waste.

Reliable checkweighers with extremely high accuracy, allows you not only to respect legal requirements, but also to avoid waste and, therefore, increase productivity.

PRISMA INDUSTRIALE S.r.l. leads the Italian market since 1984 with over 10,000 dynamic weighing systems installed all over the world on production and packaging lines:

PRISMA offers a wide range of weighing systems (with accuracy from ± 0.05 g up to 60Kg, available with IP54 and IP66 protection and MID approval) and has the know how to help you find the best solution for your market, product and packaging type, starting from the simplest weight check up to installing MID-legalized metrologic instruments.

Sturdiness and longevity are guaranteed by the top quality of the components and materials. Easily removable and washable plates allow for quick cleaning and maintenance.

Touchscreen interface permit a fast product setup and configuration, an intuitive and quick learning, maximizing productivity.

-

Add to cart

Add to cartCheckweigher 01D3 Pharma

-

Add to cart

Add to cartCheckweigher 01T3 Pharma

-

Add to cart

Add to cartCheckweigher 01W3 Pharma

-

Add to cart

Add to cartCheckweigher 08D3 compact

-

Add to cart

Add to cartCheckweigher 08T3

-

Add to cart

Add to cartCheckweigher 09D3

-

Add to cart

Add to cartCheckweigher 11D3

-

Add to cart

Add to cartCheckweigher 14D3

-

Add to cart

Add to cartCHECKWEIGHER 35D3

-

Add to cart

Add to cartCHECKWEIGHER 35T3 pharma

METAL DETECTORS

PRISMA INDUSTRIALE S.r.l., with more than 7000 installed metal detectors, is recognized from companies of any dimension (from food to pharmaceutical, from personal care to pet food) as the perfect partner to safeguard their products and protect their brand.

Following the BRC Global Standards, the metal detectors designed by PRISMA INDUSTRIALE assures high accuracy and sensitivity, detecting and rejecting defective parts from the production line, checking for ferrous and non-ferrous metal contaminants inside the products.

High sensitivity and advanced functions (i.e. self-check, phase adjustment and tracking) unite the top-level reliability and a reduction in losses caused by false rejects.

Thanks to different sized passages and conveyors, PRISMA Metal Detectors can easily inspect packaged and loose foods, tray food, powders and tablets, always respecting ISO-FDA HACCP (the hygiene and safety control standards).

Sturdiness and longevity are guaranteed from top quality of the components and materials. Easily removable and washable plates assure quick cleaning and maintenance.

An Alphanumeric graphic display permits a fast product setup and configuration, intuitive and quick learning, boosting productivity.

PRISMA INDUSTRIALE can provide food and pharma metal detectors with up to IP66 protection degree. They can be integrated into a checkweigher system.

X-Ray Inspection

X-ray machines permit to inspect features that would unidentifiable with other systems:

Any High density contaminants (i.e. bones, stones, ceramic, PVC, Teflon, glass, rubber, fibreglass, etc…)

Non-ferrous and non-magnetic stainless steel metal contaminants, even inside metal film packages or with aluminium foil

Package defects (i.e. deformations and cracks)

Completeness and fill level (even in closed packages)

Presence of necessary elements (i.e. the surprise inside a chocolate egg)

Dynamic weighing and detection of air bubbles

This system uses the differences in density and the different ray absorption levels of objects unrelated to the product.

The intuitive touchscreen interface ensures quick learning and fast configuration and product change, maximising productivity.

Low levels of radiation, use of materials that guarantee no radiation accumulation, excellent quality active and passive safety systems and complete compliance with the ISO-FDA HAACP, BRC, etc. standards, give the machine the total certainty that the product is not damaged by the X-rays and that the environment is safe for operators.

Thanks to the simple disassembly, washing operations are very quick and components require no or minimal easy maintenance.

X-Ray System can be supplied with a degree of protection up to IP65, integrated into checkweigher systems and installed within online systems for process analysis.

INTEGRATED MACHINES - CHECKWEIGHER + METAL DETECTORS

In 1995 PRISMA INDUSTRIALE S.r.l. built the first Italian integrated machine and since then has been the Italian sole manufacturer of this combined unit that guarantees total protection of the brand.

This solution gives to customers four important advantages: lower cost, reduced overall dimensions, centralised statistical analysis, a single operator interface.

The integrated machines satisfy the ISO-FDA HAACP, MID, BRC, etc. standards, and are available in different configurations adapting to a wide variety of product sizes and features.